The formula to calculate both terms, however, is mostly the same for accounting purposes. Work-In-Progress is used in the construction industry to refer to a construction project’s costs instead of a product. For example, consulting and manufacturing projects often have custom requirements based on the client. Besides these costs, ABC also incurs manufacturing overheads in the form of worker benefits, insurance costs, and equipment depreciation costs. Thus, managers can tamp down or increase production based on the availability of materials in bins on the factory floor.

Since WIP inventory takes up space and can’t be sold for a profit, it’s generally a best practice for product-based businesses to minimize the amount of WIP inventory they have on hand. In a bind, a company will find it much easier to liquidate work in process items. Though these goods are incomplete and still require some work to become finalized goods, the timespan in doing so is much shorter than work in progress goods. In addition, the market may be more willing to buy work in process goods outright if they are for standardized goods. On the other hand, work in progress is more representative of massive, one-time undertakings.

What is work in process inventory?

WIP inventory is included in the inventory line item as an asset on your balance sheet. The two other types of inventory are raw materials (the beginning materials used to manufacture a product) and finished goods (the fully assembled products ready to be sold). In general, Work-In-Process inventory refers to partially completed goods that move from raw materials to a finished product within a short time frame. Work in progress inventory is more valuable than raw materials that have yet to be put into manufacturing use but is not more valuable than a company’s finished goods or finished inventory ready for sale. In essence, work in progress inventory is the middle stage of the production process between raw materials and the finished product.

You can reduce your work in process inventory by adjusting your manufacturing processes, investing in employees, and using inventory management software. The cost of manufactured goods (COGM) refers to all the costs incurred to make a final product. You need to know the final COGM to calculate the value of your current WIP inventory value. Work in progress assets are much larger endeavors and may require capitalization if the work in progress investment is not an inventory item.

Where do I account for WIP inventory on my balance sheet?

If raw material is combined with direct labor but is not ready to be sold, it counts as WIP inventory. For example, if a company sells bags of coffee, their WIP inventory would include bags, labels, coffee beans, and shipping work in progress example boxes. For some, work-in-process refers to products that move from raw materials to finished products in a short period. Work in progress (WIP) refers to partially-completed goods that are still in the production process.

- For instance, the WIP inventory could be undergoing finishing touches prior to being marked as complete.

- Work in progress assets are much larger endeavors and may require capitalization if the work in progress investment is not an inventory item.

- The general ledger account used to track work in progress is the work in progress inventory account.

- Evaluate production processes, materials, and supplier relationships to optimize costs without compromising quality.

- At the second workstation, the pin on which the butterfly pivots is discovered to be of the wrong dimensions in some instances and, as a result, cannot be added to the carburetor assembly.

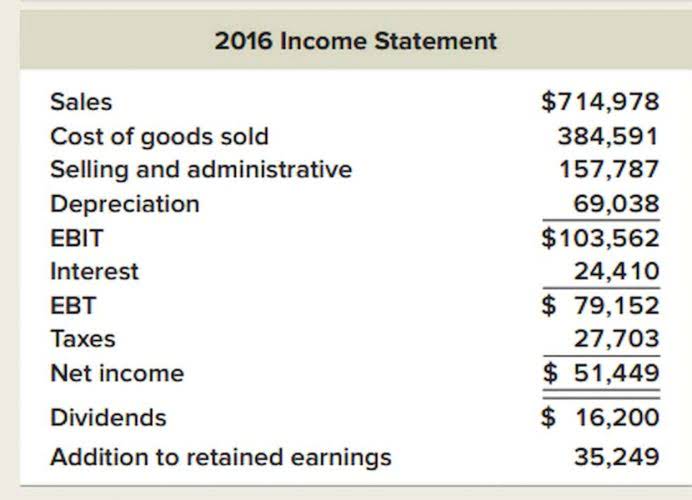

- Total WIP Costs are calculated as a sum of WIP Inventory + Direct Labor Costs + Overhead costs.

Ask a question about your financial situation providing as much detail as possible. This team of experts helps Finance Strategists maintain the highest level of accuracy and professionalism possible. Our team of reviewers are established professionals with decades of experience in areas of personal finance and hold many advanced degrees and certifications. Once the product has moved past WIP, it is classified as a finished goods inventory.

What Is the Difference Between Work in Process and Work in Progress?

One of the advantages of calculating it manually will be you can add expenses like the cost of scrap, spoilage of raw material, etc. as well in it since it is all visible during physical counting. MYOB offers robust inventory management and warehouse management solutions to help you identify production bottlenecks, calculate a more accurate business valuation and reduce your WIP inventory. Calculating your WIP value is a time-consuming process, so it’s easier and more efficient to use inventory management software.

Lascia un commento